A LEGACY OF INNOVATION AND CRAFTSMANSHIP

CEO and Founder, Francis Phillips

Nearly 50 Years ago, PPM was founded by one man, with a clear mission – to bridge the gap between engineering and manufacturing.

What Francis Phillips set out to do long ago with his wife Jeanne by his side, today serves as our compass; the guiding principles behind the steady growth of our company and our ability to create programs and services that support the unique needs of OEMs.

We believe in working closely with our customers, and as a result, are able to function as a natural extension of their business. It’s then that the true nature and depth of our capabilities becomes apparent.

Phillips Precision Medicraft, OEM-centric from the very beginning.

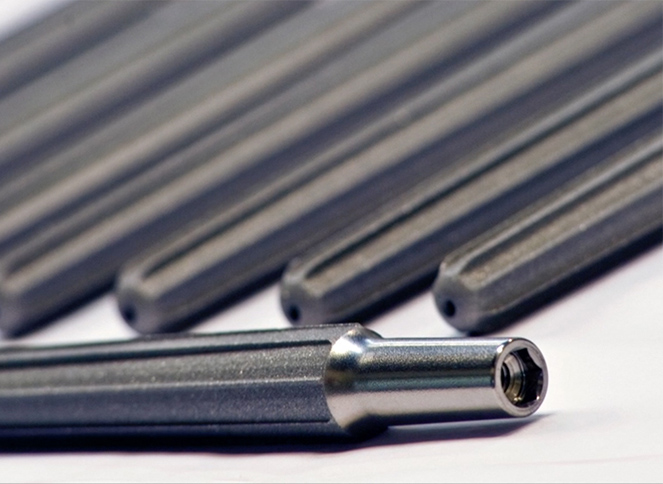

IMPLANTS AND INSTRUMENTATION

Creating OEM-centric Solutions that Work

How Phillips Precision Medicraft meets the rigorous demands of a global orthopedic marketplace.

Strong relationships create great partnerships. Our goal is to become a natural extension of your business, giving us the opportunity to seamlessly adapt and integrate lean manufacturing disciplines with value stream partnerships that work.

Rapid Prototyping, Fast-track Manufacturing, Vendor Managed Inventory are just a few of the customized solutions we offer our OEM partners. Contact us to learn more.

Form and Function With Style

World-class Design Makes a World Of Difference to Your Brand

When case and tray artistry meets engineering innovation, great things happen.

Passion and creativity drive the high impact designs we develop. Building real partnerships with our OEMs allows us to uncover the best solution for a given project. Our experience allows us to prepare strategies that get the greatest value out of every operation in the manufacturing process. Together, we’re able to meet the needs of the OEMs we serve by delivering cases and trays with form, function, and style, on-time and on-budget.

PPM Delivery Systems, Cases and Trays – American Made, Made to Stand Out.

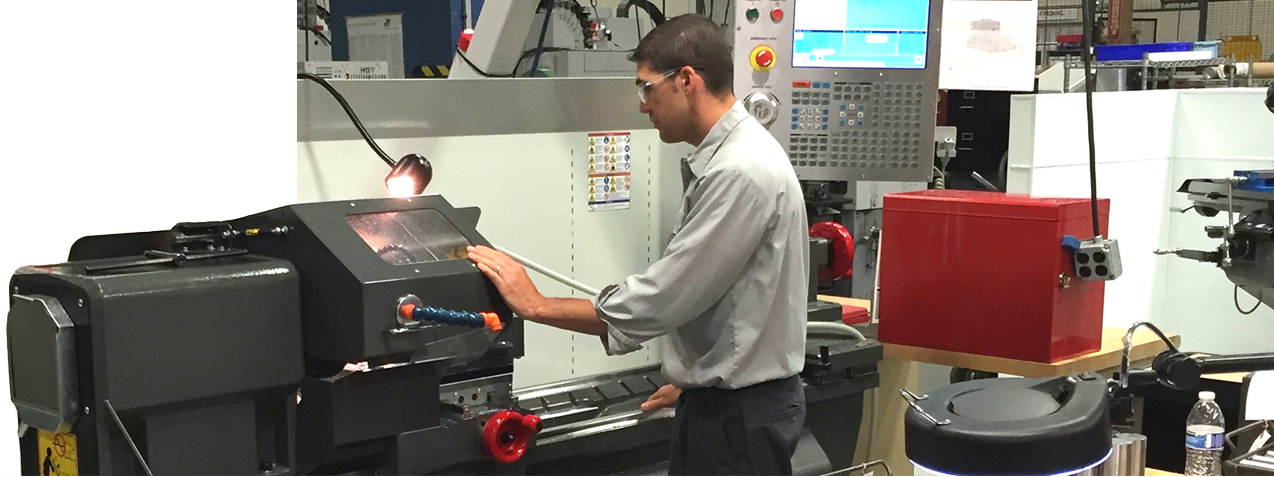

LEAN Manufacturing | 5S | Continuous Improvement

Results in FAME (Flexible, Adaptable, Advanced Manufacturing Environment)

By integrating LEAN manufacturing principles along with 5S and Continuous Improvement methodologies we’re able to provide OEMs with what they need most, FAME – a contract manufacturer with a Flexible Adaptable Manufacturing Environment

FAME allows PPM to maximize the capabilities of our manufacturing environment and take advantage of our fully cross-trained staff. From on-demand legacy products (through our VMI program) to rapid prototyping services (for refining designs and verify manufacturability with speed, accuracy) our highly flexible manufacturing environment features adaptable work cells to deliver what our customers need, when they need it, while maintaining quality standards.

Creating world-class custom solutions to realize an OEM’s complete vision and help them maintain a critical competitive advantage.

Rapid Prototyping

Our new Rapid Prototyping is the perfect addition to our highly sought-after DFM service. Strategically designed to support OEM partners who require; product manufactured from their prints quickly or to test formal DFM results from our in-house engineering team. Our rapid prototyping service allows select customers to refine designs and verify manufacturability with speed and accuracy.

THE PPM

NEWS FEED

Phillips Precision Medicraft engineers and manufactures advanced orthopedic implants, instruments and delivery systems. Offering service-driven solutions that really work.

2017 Annual Meeting – Booth #5209: March 14-18 San Diego, California

Visit our team at booth #5209 to learn about PPMs highly flexible and adaptable manufacture environment. Designed specifically to support the unique needs of our OEM partners. To schedule an on-site meeting, please contact Jack

Fast-Track Manufacturing – part 2

A Step Beyond Rapid Prototyping As we look back the many manufacturing projects from last year and prepare to launch programs and services for 2017, our thoughts came back to one specific project, with good

OMTEC 2017 – Booth 242: Chicago | June 14-15, 2017

Join us at the 13th Annual Orthopaedic Manufacturing & Technology Exposition and Conference - Donald E. Stephens Convention Center | Chicago | June 14-15, 2017. Visit our team at booth #242 to learn about PPMs