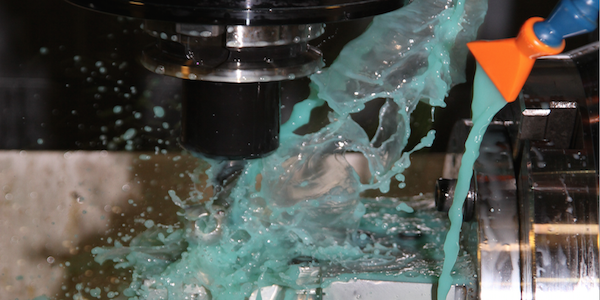

Lean Manufacturing Methodology Leads to Favorable Purchasing Programs for OEMs

PPM has always taken a partnership approach with our customers. In doing so, we’ve been able to continually adapt our business to fit their needs. This year our continuous improvement efforts have resulted in the development of KANBAN pull systems and vendor managed inventory programs that really work.

By applying value stream methodologies, we can create capacity for products that meet lean manufacturing criteria. Meeting the criteria is critical to the success and effectiveness of the program. The model utilizes dedicated resources to produce products at a lower cost with virtually no lead times once a product has been identified and value streamed.

The benefits include:

- Reduced setup, increased process improvements, while maintaining superior quality.

- Automated resource scheduling.

- Dedicated capacity resources for qualifying products.

- Inventory management programs that allow us to ship product in days rather than weeks.

- Favorable pricing.

- Product Qualifications:

Volume Product:

- A steady flow of product usually within a family of sizes allowing a dedicated resource strategy. Using our ERP (Enterprise Resource Planning) system to accurately reserve capacity for the proper sizes at the proper times.

This VMI Purchasing Model is designed to provide you with superior process control, fast turnaround times, and effective inventory management.

Contact our business development team with questions, comments or to see if you have product(s) that qualify for PPM’s VMI Service Program.

Get Social