Creating Custom Solutions to Meet OEM Needs

We’ve always said that quality products start with quality relationships. The following additive manufacturing initiative is a testament to that belief. Each additive manufacturing product has its own unique challenges. In some cases, the geometry is difficult to produce using conventional manufacturing methods such as milling, turning or casting. This is even more evident when a device is one solid piece. Despite the challenges, it’s still necessary to deliver a consistently uniform product that meets both quality and aesthetic standards.

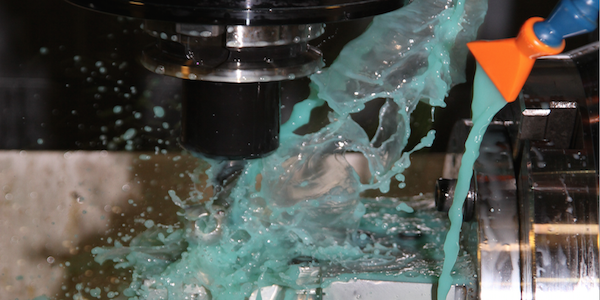

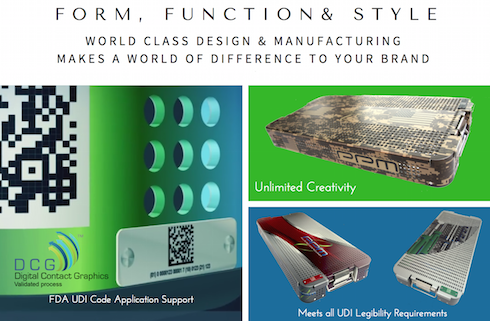

PPM’s engineering team worked on a tibial base plate used in reconstructive knee surgery. Initially produced using a 3D laser sintering process, the product was supplied as a single substrate containing a rough and semi-rough surface finish and produced to within .0002 tolerance. The OEM’s request was straightforward: provide a finished machined outer surface for the tibial base plate and support the product validation process. Our “value add” included adapting fixtures, tooling and developing a manufacturing build plan to meet the quality and validation requirements of our customer.

Every PPM initiative begins with a thorough DFM (design for manufacturability) review. The first challenge was finishing one side of the implant without affecting the surface roughness on the opposite side. However, it wasn’t possible to provide the desired cosmetic finish by using traditional fixturing, and custom fixturing would have increased the cost. Our team suggested the OEM add an edge to the implant that would allow us to grip the part and finish the piece cleanly without impacting the necessary surface roughness. The OEM subsequently printed new parts with a ledge that would be eventually removed, and this worked perfectly.

Another challenge: providing a uniform and aesthetic appearance without bead blasting. Various options were discussed, including the use of washable fish glue used as a masking agent, which did not perform as expected. The best way to create the type of finish they sought, while protecting the rest of the tibial base plate, was hand sanding. Unfortunately, this meant extending manufacturing timelines. Ultimately, we decided to create a custom spring-loaded tool that delivered the desired finish far more effectively.

The validation process was lengthy as expected, and many manufacturing changes were made and documented along the way. As changes were implemented, PPM developed a custom multi-stage cleaning and passivation process during the final stages of manufacturing process development.

“We really enjoyed working this particular project because it felt like we were a natural extension of our OEM’s internal department throughout the entire R&D process,” said Rich Bertinato, PPM engineer. “The steady dialogue between our teams was very productive and allowed us to create tactical paths that identified issues and successfully develop solutions together.”

PPM is always excited to have the opportunity to truly partner with our OEM customers and create solutions that meet and often exceed expectations.

Get Social