A Step Beyond Rapid Prototyping

Our commitment to developing custom solutions for OEMs is based on two distinct factors: 1) customer need and 2) promoting organic growth and the evolution of 5S and Lean Continuous Improvement efforts. Both have cultivated the kind of diverse and adaptable manufacturing environment that makes offering unique custom solutions possible.

Consider this Case History

A visiting OEM presented PPM with a trauma implant product that had one very challenging deadline. Our management and engineering teams listened carefully and determined that with our flexible manufacturing cells, it would be possible to meet the deadline. Having the experience and quality control systems established, it should have been a matter of simply applying the existing process to the new geometry.

Product and Project Details

The product is a trauma implant designed to address severe fractures. Under certain circumstances, a physician would have the opportunity to use healthy areas of the remaining bone and affix the implant to give the patient full use and mobility. Our customer required a finished product ready for cadaver lab review and validation testing in just a few weeks.

Timeline: From kickoff to final product in just over 3 weeks

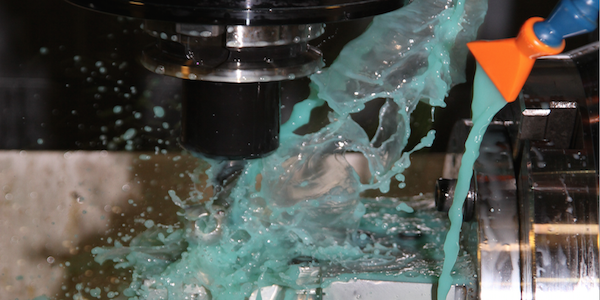

Engineering began on February 12th (with client-supplied prints and geometry), and the final product was delivered on March 8th. Steps included:

- Complete DFM (Design for Manufacturability): Collaborate with customer and provide support to develop final product specifications.

- Control Plan: Roadmap that defines the manufacturing process.

- Schedule: Create necessary capacity within the manufacturing facility.

- Manufacturing: From raw material to finished product.

- Delivery: On-time delivery of the product to meet deadline.

How We Did It

The solid geometry we received did not have final specification defined. This gave us the opportunity to work together as an extension of our OEM’s engineering team to define not only the final specifications but to create the ideal manufacturing solution (a huge plus).

Fast-track manufacturing requires more advanced strategic planning and coordination. Engineering, inspection criteria, quality control reviews were all running in tandem throughout the manufacturing process. This approach requires a great deal of human interaction in order to be successful. Computers alone simply could not have managed all that was necessary. Employing a one-piece flow approach was also an integral part of the strategy that allowed us to succeed. It was very gratifying to see how well one operation seamlessly flowed into the next, driven by our dedicated manufacturing team.

PPM delivered the product on time to our customer, and in doing so validated our understanding of their unique needs and the flexibility of our manufacturing environment.

Keep an eye out for Part II of this blog, where we will detail all aspects of the 2nd phase of the project: validation and testing.

Get Social