Fast-Track Manufacturing – part 2

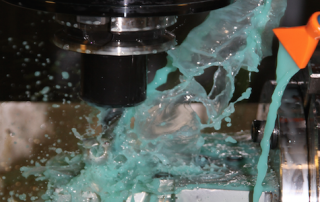

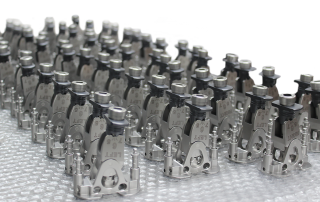

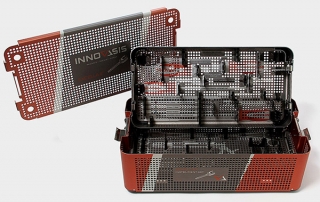

A Step Beyond Rapid Prototyping As we look back the many manufacturing projects from last year and prepare to launch programs and services for 2017, our thoughts came back to one specific project, with good reason. More than any other year, 2016 showcased the flexibility and adaptability of our engineering and manufacturing departments. Last April,

Get Social