For years, we have seen many changes in our industry, the case and tray business, including our OEMs’ own R&D departments. One constant demand is always “lighter is better,” which is met by altering designs, adding plastic features and more ventilation holes, etc. Other items such as case-latching techniques, case feet, handles and stacking abilities are also always addressed. Items like these (with cost-effectiveness in mind) have changed dozens of times, but the graphics really have not changed much at all due to the harsh environments they are put through and what has been available to us.

Today, case and tray graphics continue to be silk screened using 2 part epoxy inks from only a few major manufacturers in the United States. These inks are manufactured to work in a wide variety of industries but not specific to medical. The ink companies will not certify their performance in any industry, especially the medical industry. These inks are simply just not designed to withstand the harsh cleaning environments. There are also many human factors in the screening process. From a manufacturing standpoint, this is something we’ve never felt comfortable with. In fact, there are over 500 different elements in the screen printing process that could yield failure in the field of any industrial application. Top consultants in the screen printing field agree.

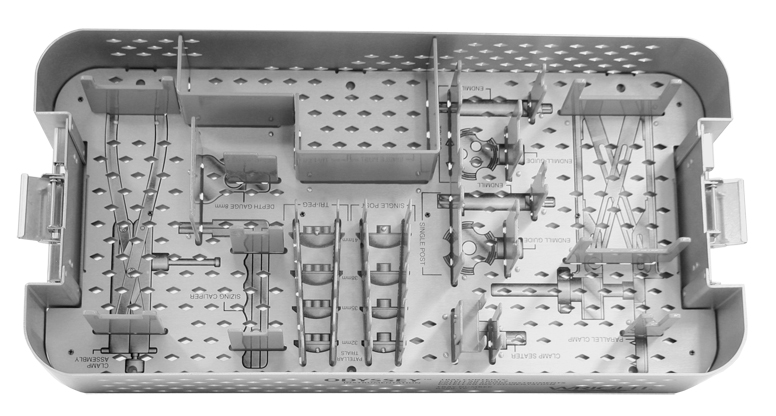

Twenty years ago, when Medicraft (known as PPM now) began, cases and trays were silk- screened with these inks because of high usage and client requests. We would lay down basic outlines of the instruments and implants. After approximately five years, Medicraft innovated the screen technique called “vector graphics.” This application added depth perception to the instruments and implants by adding half tones to the outlines.

Twenty years ago, when Medicraft (known as PPM now) began, cases and trays were silk- screened with these inks because of high usage and client requests. We would lay down basic outlines of the instruments and implants. After approximately five years, Medicraft innovated the screen technique called “vector graphics.” This application added depth perception to the instruments and implants by adding half tones to the outlines.

As this became the standard throughout case and tray manufacturing, we were still limited to the silk-screening process and subject to the same failure possibilities. Even when silkscreen performs at its maximum, the success rate will still not outlast the product, leaving OEMs at a loss.

Silkscreening is an analog process. For every color in an image, there has to be a physical screen manufactured from artwork, then to film, then to screens. In some cases, we have over seven different colors in a case and tray, which would yield seven different physical screens. The cost of seven screens for one-time charges in development is not appealing. Just imagine having over 1,000 different products in a manufacturing facility that will need a minimum of two different screens for inside the tray and outside the tray, not to mention multiple colors. All of these screens have a shelf life of approximately five years depending on use. These screens wear out from usage and harsh cleaning agents, which in turn means the silkscreens have to be purchased again, something our clients are not keen about since the cost can come out of their budget.

Silkscreening is an analog process. For every color in an image, there has to be a physical screen manufactured from artwork, then to film, then to screens. In some cases, we have over seven different colors in a case and tray, which would yield seven different physical screens. The cost of seven screens for one-time charges in development is not appealing. Just imagine having over 1,000 different products in a manufacturing facility that will need a minimum of two different screens for inside the tray and outside the tray, not to mention multiple colors. All of these screens have a shelf life of approximately five years depending on use. These screens wear out from usage and harsh cleaning agents, which in turn means the silkscreens have to be purchased again, something our clients are not keen about since the cost can come out of their budget.

Then there’s traceability. All of these screens must be stored and their whereabouts tracked at all times. At PPM, we employ a barcode system for this and it’s still time intensive. Due to the workload, like our OEMs, we send some screening projects to our vendors, so traceability is important. This also adds cost when making a new screen for revisions. Imagine having to destroy expensive screens because a single number changed on an instrument’s part number. Multi-colors are another problem. Clients will either stay away from this due to its process, time and cost, or will reluctantly do it because it’s required of them. Every time different colors are featured on one side of the tray (i.e., the inside graphics), you must screen a color, dry it in an air-circulated oven for a length of time, let cool and now produce the second color, and so on.

For years we were looking for alternatives to silk screening, knowing there had to be something out there that would eliminate such an outdated process and bring case and tray graphics into the digital age. Three years ago, we decided to research graphics applications that were radically different from what our industry was accustomed to for the past 20 plus years.

Discovering the Digital Contact Graphics™ (DCG) process required two years of extensive research, trials, errors, and long development hours. Finally, we created a bio-compatible imaging process that sits below the surface of the anodic coating of standard aluminum cases and trays. Our internal testing, along with outside lab testing and reports as well as two years of client feedback, indicate that DCG is durable far beyond the silk-screening process. It’s also much safer than traditional silk screening as the review of MSDS sheets (material safety data sheets) reveal. We have also received very positive feedback from our clients and their customers who are impressed with the zero failure rate.

Discovering the Digital Contact Graphics™ (DCG) process required two years of extensive research, trials, errors, and long development hours. Finally, we created a bio-compatible imaging process that sits below the surface of the anodic coating of standard aluminum cases and trays. Our internal testing, along with outside lab testing and reports as well as two years of client feedback, indicate that DCG is durable far beyond the silk-screening process. It’s also much safer than traditional silk screening as the review of MSDS sheets (material safety data sheets) reveal. We have also received very positive feedback from our clients and their customers who are impressed with the zero failure rate.

Our process is currently under evaluation for its patent process, which should be complete over the next few months. We’re able to secure this patent because our process is distinctly different than anything else in our industry. And our DCG process is now validated at PPM. If you have a vendor doing this in house, it would be prudent to ask if theirs is a “validated” process.

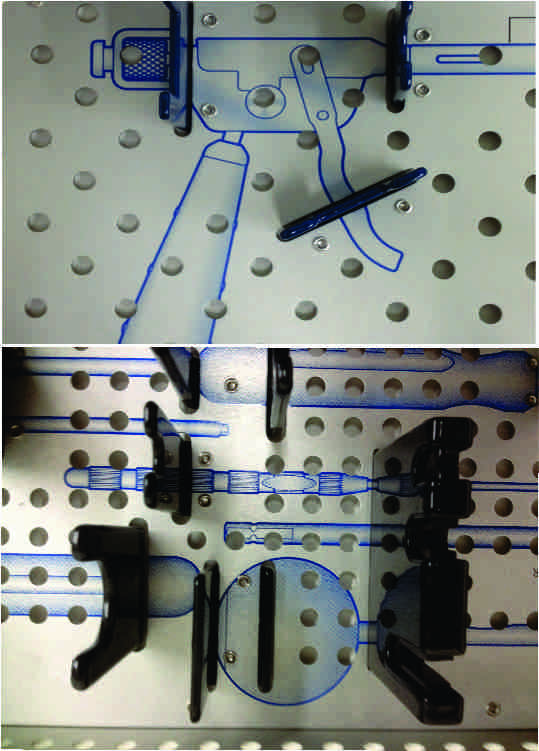

Digital Contact Graphics have produced many major results compared to other graphics programs in the industry. First and foremost, since the models supplied to  engineering today are far better than years ago, our art department is able to create images that are photorealistic for your clients. Imagine going from a case with just one company color silk-screened 2D vector graphics to 3D crystal-clear images.

engineering today are far better than years ago, our art department is able to create images that are photorealistic for your clients. Imagine going from a case with just one company color silk-screened 2D vector graphics to 3D crystal-clear images.

There are many ways to employ images with your cases and trays. We can provide actual photographs to lay down if customers provide us with instruments and implants before they start to think about cases and trays. We’ve also built custom modeling software for our company and artists to effectively implement this process.

There was a question brought up recently by one of our customers that made sense, and we had to figure it out: If you’re the only vendor out of our five that can provide this process, how can we lay down your graphics on our trays and have our other tray vendors continue with conventional silk screening? To accommodate them, since they’re obligated to have more than one case and tray vendor, we decided to “dumb down” the graphics to match the look of silk-screened graphics. We made one sample of each for evaluation. From two feet away, two different people chose the DCG tray when asked which one was silkscreened.

This company now has the choice of not sending all of their case work to us, but they can send us their top sellers with higher quantities to start saving money.

This company now has the choice of not sending all of their case work to us, but they can send us their top sellers with higher quantities to start saving money.

Color anodize. We know what color anodize finishes look like after visiting an autoclave time and again. Some colors receive different results; DCG receives the same result no matter what color. Color anodizing is costly, and more parts have to be engineered for the aesthetics of your case if you choose to go this route. With DCG, we now replace costly color anodizing for your cases. Since the colors are embedded into the aluminum and not on the surface, you cannot scratch the color like you would a color-anodized part.

Smart Cases: Because this is new technology, Medicraft is (currently) the only provider to offer you QR coding. We’ve set the ball rolling with a few clients, and it is definitely catching on. We now offer QR code cases that link doctors, marketing and hospital personnel with your information. It’s as simple as holding your PDA device to the side of a case and code; it will then direct your customers to any  information they might need. This includes and is not limited to company websites, product information, cleaning instructions, marketing video and techniques on usage of the product, inventory etc. And since these graphics are scratch resistant, you will always be able to scan it. Our clients simply create the URL and we provide the QR code. Every piece is tested during production. The cost of all of this? Nothing, it’s part of the art work you are already paying for. Best of all, this new DCG technology is safer for the end user. Unlike silk-screening inks, it’s impossible for it to wind up in someone’s body because it doesn’t sit on the surface and instruments cannot get to it. With all of the FDA regulations our customers have to deal with, this is one more feature they are sure to love.

information they might need. This includes and is not limited to company websites, product information, cleaning instructions, marketing video and techniques on usage of the product, inventory etc. And since these graphics are scratch resistant, you will always be able to scan it. Our clients simply create the URL and we provide the QR code. Every piece is tested during production. The cost of all of this? Nothing, it’s part of the art work you are already paying for. Best of all, this new DCG technology is safer for the end user. Unlike silk-screening inks, it’s impossible for it to wind up in someone’s body because it doesn’t sit on the surface and instruments cannot get to it. With all of the FDA regulations our customers have to deal with, this is one more feature they are sure to love.